The world’s largest steelmaker, ArcelorMittal, which plans to temporarily close several operations in Europe due to a drop in its order book and the explosion in energy prices, forecasts a fall in its steel production of 1.5 million tonnes in the fourth quarter of 2022 in Europe compared to the previous year. The group announced at the beginning of September the temporary closure of several blast furnaces and other infrastructures…

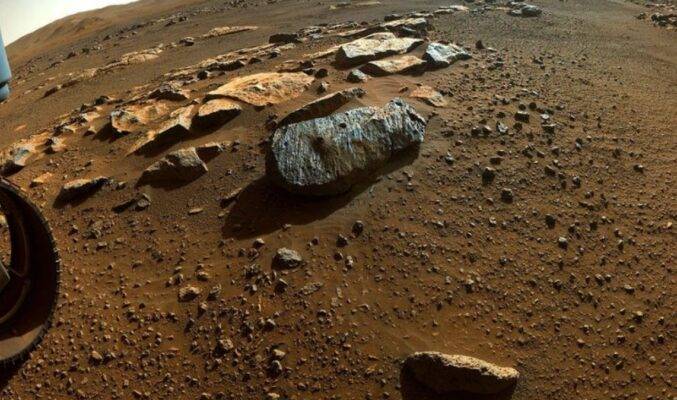

Martian metal industry: air, sun and regolith

Engineers from the Australian University of Swinburne (Swinburne University of Technology) have developed a process for the production of iron from scrap materials on Mars. It uses Martian soil – regolith, processed air and solar energy. Solar radiation is used as a heat source, in addition, carbon is involved in the scheme (carbothermic reaction) as a catalyst. It can be obtained by cooling carbon monoxide (CO). In turn, CO is…

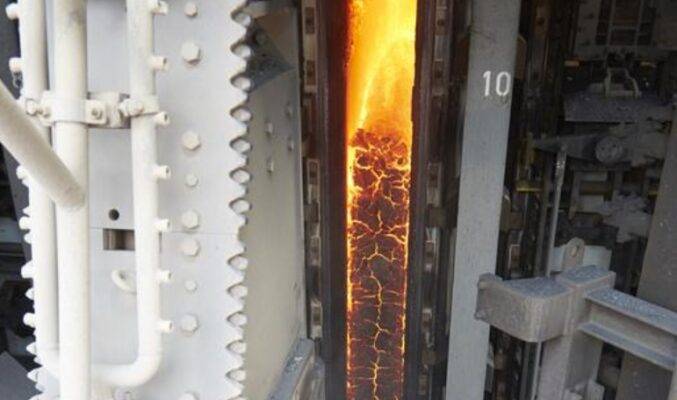

Recycle CO2 in the blast furnace: climate-friendly steel

Germany is the largest steel producer in the EU. Around a third of the carbon dioxide (CO2) emitted by the entire industry in Germany is produced in blast furnaces. However, an alternative process route is in sight that produces almost no CO2. However, it will only be fully established in many years. For the transition, engineers are developing a concept under the coordination of the University of Duisburg-Essen (UDE) to…

Concerns about the future in the metal and electrical industry

The topics of natural gas and corona infections are depressing the mood in the Lower Bavarian metal and electrical industry. Many companies are unsure. At the same time, the employers’ associations warn against wage demands that are too high. The situation in the Lower Bavarian metal and electrical industry is tense. There is great uncertainty. This is the result of the summer business survey conducted by the Lower Bavarian metal…

Steel collective bargaining breakthrough

Wages and salaries are expected to increase by 6.5 percent from August. IG Metall speaks of the largest percentage increase in the steel industry for 30 years. After difficult negotiations and warning strikes, IG Metall and the employers have agreed on a new collective agreement for most of the German steel industry. As of August 1, wages and salaries are to rise by 6.5 percent, as announced by the trade…

Britain to present plan to safeguard steel trade

Britain will present its steel trade safeguard plan on Wednesday, days after proposing broader tariffs to protect local steelmakers, a move that could breach international trade rules. Trade Minister Anne-Marie Trevelyan will make a statement in parliament on steel safeguards after 1130 GMT, the House of Commons leader said on Twitter. These safeguards can include import restrictions ranging from tariffs to quotas. Britain last week proposed extending a package of…

Features of stainless steel sheet products

Stainless steel sheet products may have different appearance and properties – it depends on the alloy grade and manufacturing method. Matte steel is traditionally used in the production of medical instruments, as well as in construction and decoration. The spectacular shiny metal is preferred by builders of premium buildings. The price of stainless steel sheet products can be different, and it also becomes one of the selection criteria. Stainless steel…

Belt conveyor

The belt conveyor with discharge trolley is used in the majority of production plants: in agriculture, mining, chemical and food industry. In metal industry, in ports, in warehouses etc. these conveyor belts are used without fail. Why conveyor belts are used? The belt conveyor is a high-capacity unit. This is independent of its travel speed and length. It is used both as part of a machine set and as an…

Excavator bucket technology and manufacturing process

Development of Documentation In the first phase, engineers and planners. They study the purpose of the bucket and the excavator model, because we need to understand what the bucket will be used for and what machine it will be fitted to. Then a decision is made regarding the steel grade and thickness of the steel sheet that the bucket and its components are to be made from. These calculations are…

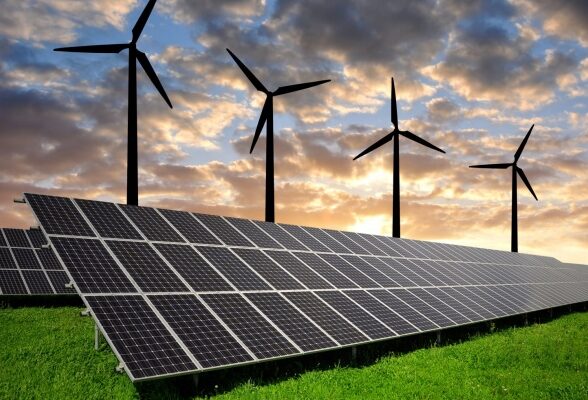

A “beautiful green future” awaits the global steel industry

Several conferences around the world in late second and early third decade of June have looked at the global transition to a carbon-free economy and its implications for the metals industry, among other issues.Richard Horrocks-Taylor, Global Head of Metals Research, Standard Chartered Bank, told the Qatar Economic Forum that the metals industry will be undergoing a radical transformation and relocation over the next 10-15 years. According to him, if earlier…