Stainless steel sheet products may have different appearance and properties – it depends on the alloy grade and manufacturing method.

Matte steel is traditionally used in the production of medical instruments, as well as in construction and decoration. The spectacular shiny metal is preferred by builders of premium buildings. The price of stainless steel sheet products can be different, and it also becomes one of the selection criteria.

Stainless steel sheet products: the benefits of sheet metal

Stainless steel is an iron-based alloy, among the characteristics of which the following stand out:

- durability;

- fire resistance;

- resistance to high temperatures;

- increased strength;

- spectacular appearance, etc.

The material is environmentally safe, it does not cause allergic reactions. Long term operation of stainless steel products does not affect them, as steel is not subject to corrosion, rotting and mold, it is not afraid of mechanical damage.

In this case the resistance of the alloy to corrosion can be said by its content of chromium. If the latter is a little, then these properties will be manifested only under normal conditions, but not in aggressive environments. When the chromium content exceeds 17%, we are talking about a material that can be rightfully called stainless steel. The minimum allowable level of presence of this element in the alloy is 10.5%.

Types of stainless steel rolled products

Going to buy products from sheet steel, it is necessary to know what options are present in the modern market.

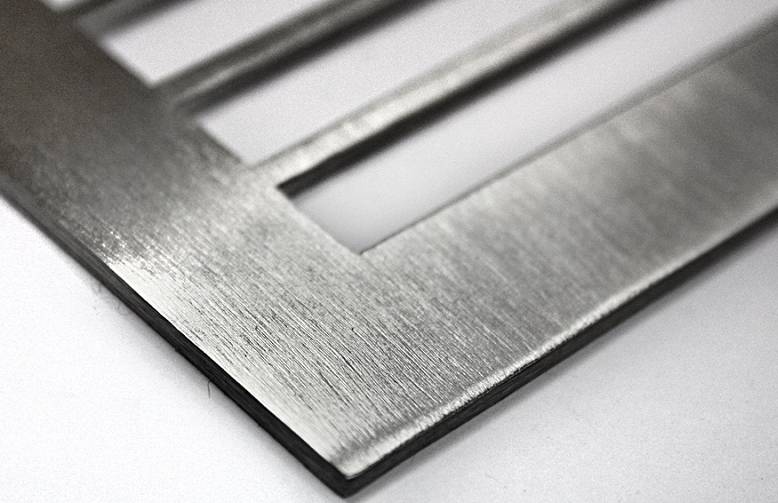

- Matte sheets. The level of processing is minimal, the surface is simply processed with abrasive materials, after which it acquires a characteristic matte finish;

- Polished, brushed, mirror surfaces. The production technology in this case is much more complicated. For additional polishing, abrasives and various brushes are used. It is possible to achieve an ideal condition of the sheet – then it is practically indistinguishable from a mirror;

- corrugated. A special pattern is applied to the surface, for example “lentil” or “duo”. Its main function – to provide anti-slip and make the sheet looks attractive. Choosing this option, you should take into account that the thickness of the product is always specified without protrusions;

- decorative. On the sheet is extruded pattern, with its texture can be different and imitate leather, drizzle, etc. Relief can be felt when touching, the reverse side of the sheet is often smooth.

Manufacturing methods

Stainless steel sheets are made by using hot and cold rolling. When using the “cold” method, it is possible to obtain a sheet thickness of 0.4-0.5 mm with a matte smooth surface. A mirror-like shine is achieved by using an ammonia medium in which the product is immersed.

Hot-rolled versions have a thickness of 2-50 mm. The surface of such a sheet will be matt, with roughness, and resistance to corrosion will be increased.