In a metal manufacturing facility, it’s not merely about estimating the laser machine’s cutting time

In the machine tool industry’s supply side, we often discuss machine performance metrics. What’s the cutting speed for half-inch steel using nitrogen? How long does the piercing take? What’s the acceleration rate? Let’s conduct a time study to assess the overall run time! While these are valid starting points, are they truly the factors we should prioritize when contemplating the recipe for success?

Run time serves as the cornerstone of a successful laser cutting business, but it’s essential to consider more than just the job’s cutting duration. Relying solely on cut time for quoting can be disheartening, especially when profit margins are slim.

The True Cost Per Part

To uncover any concealed expenses in laser cutting, it’s crucial to analyze labor efficiency, machine availability, consistency in operation duration and part quality, possible rework, and material efficiency.

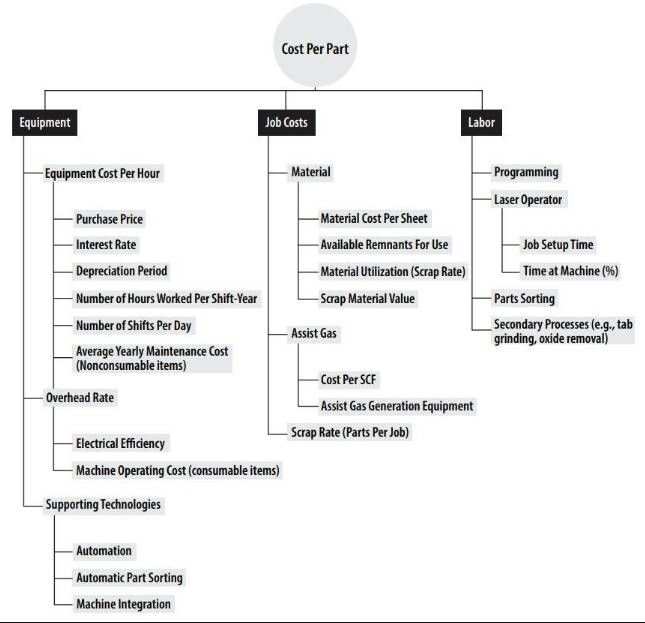

Generally, part expenses can be categorized into three main groups:

- equipment,

- job-related expenses (such as materials acquired or assist gases utilized),

- labor.

These costs can then be further subdivided into finer details (refer to Figure 1).

When we compute the expense of a project or the cost per individual part, each element listed in Figure 1 contributes to the overall expenditure. However, the complexity arises when we evaluate a cost within one category without thoroughly assessing its implications for costs in another category.

Process Stability

The concept of optimizing material usage may not be groundbreaking, but we must assess its advantages in comparison to other factors. When determining the cost of a component, it becomes evident that, in the majority of instances, material accounts for the most substantial portion of the overall cost.

To maximize material utilization, we can employ tactics like common-line cutting (CLC). CLC is beneficial for conserving both material and cutting time, as it enables the simultaneous creation of two part edges with a single cut. However, it is essential to acknowledge the limitations of this technique. CLC’s effectiveness is heavily reliant on the geometry of the parts. Smaller components that are susceptible to tipping may still need to be connected with tabs to maintain stability during the process, and these connected parts will require separation and potentially deburring, which entails additional time and labor costs.

The process of separating parts can be especially challenging when working with thicker materials. Laser cutting technology has introduced a solution by enabling the creation of “nano” tabs positioned well into the cut thickness. The creation of these tabs does not affect the overall run time, as the laser beam remains within the kerf, eliminating the need to re-enter the material after the tab is formed (refer to Figure 2). It’s worth noting that this technology is currently available on specific machines. This example underscores how recent advancements in laser cutting are no longer solely focused on increasing cutting speed.

Nozzle Placement and Nitrogen Flow

Once more, common-line cutting (CLC) heavily relies on the geometry of the parts, making it impractical to completely eliminate web widths in most cases. Instead, the goal is often to reduce the width of the web. However, this can raise concerns about parts tipping and potentially leading to collisions. Machine tool manufacturers provide various solutions to address this issue, but one universally accessible approach is to increase the nozzle offset.

In recent years, there has been a trend towards reducing the nozzle-to-workpiece distance. The rationale behind this trend is straightforward: Fiber lasers are exceptionally fast, especially when dealing with high-powered fiber lasers. This remarkable boost in performance necessitates a corresponding increase in nitrogen flow rates. High-powered fiber lasers have the capability to vaporize and melt metal within the kerf significantly faster than traditional CO2 lasers.

Instead of reducing the machine’s speed, which would be counterproductive, we make adjustments to the nozzle’s position relative to the workpiece. This modification enhances the flow of assist gas through the kerf without raising the pressure. It seems like a great solution, but with the laser still operating at a high speed, the occurrence of tip-ups becomes a more significant concern.

If the software struggles with frequent part tip-ups, opting for a cutting technique with a greater nozzle offset might be a logical choice. However, the suitability of this approach depends on the specific application. It involves balancing the need for program stability with the higher consumption of assist gas that accompanies a greater nozzle offset.

Another alternative to address part tipping is the inclusion of slug-destructs, which can be generated manually or automatically through software. In this scenario, a decision must be made. Slug-destruct operations enhance process reliability but come with higher consumable expenses and a potential program slowdown.

The most rational approach to determine whether to implement slug-destructs is by assessing the probability of a part tipping. If there’s a significant likelihood of tipping and programming solutions to avoid collisions are not feasible, several alternatives are available. These include using microtabs to secure parts or cutting the slug in a way that allows it to safely drop out of the way.

If the problematic contour encompasses the entire part, we won’t have any other choice but to use tabs. However, when it’s an interior contour causing problems, we should assess and compare the time and cost implications of using tabs versus slug destruction.

Now the cost considerations come into play. Will the addition of a microtab make it more challenging to remove the part or slug from the nest? Opting for a slug-destruct method will extend the laser run time, which increases costs. So, the decision ultimately hinges on whether it’s more cost-effective to allocate additional labor for part separation or to endure the increased run time at the machine’s hourly rate. The final choice may depend on the quantity of slugs that need to be cut into smaller, manageable pieces, given the machine’s higher hourly rate.

Labor Factors

Labor constitutes a significant cost factor, and it becomes crucial to control when striving to compete with low-labor-cost markets. In laser cutting, labor is linked to initial programming (although costs decrease for subsequent runs of repeat orders) and the labor involved in operating the machine. The higher the level of automation in a machine, the smaller the portion of a laser operator’s hourly rate that we need to allocate to the job.

“Automation” in laser cutting typically encompasses material handling and sorting, but there are various forms of automation integrated into modern laser systems. These contemporary machines feature automated nozzle changing, active monitoring of cut quality, and feed rate control. While they do represent an initial investment, the labor savings they provide can often substantiate the expense.

The hourly rate for a laser machine is determined by its throughput.

Consider a scenario where a machine can accomplish in one shift what previously required two shifts

In such a case, transitioning from two shifts to one can effectively double the machine’s hourly rate. By increasing the productivity of each machine, we can decrease the overall number of machines needed to complete the same workload. When we cut the number of lasers in half, we are also cutting our labor expenses in half.

About OEE

Naturally, these cost savings become irrelevant if our equipment lacks reliability. Several processing technologies play a crucial role in ensuring the continuous operation of laser cutting, such as

- machine status monitoring,

- automatic nozzle inspections,

- and scattered light sensors that identify contamination on the protective glass of the cutting head.

In today’s context, modern machine interfaces offer intelligent features that can provide estimates of the time remaining until the next servicing.

All these functionalities contribute to the automation of specific machine maintenance tasks. Whether we are equipped with a machine boasting these capabilities or we adhere to traditional maintenance methods, which involve manual effort and a proactive approach, it remains crucial to perform maintenance duties diligently, efficiently, and within the recommended timeframes.

The rationale behind this approach is straightforward: maintaining the machine in peak operational condition is essential for sustaining high overall equipment effectiveness (OEE), which is calculated as the product of availability, performance, and quality. In simple terms, OEE measures the percentage of manufacturing time that is genuinely productive.

A perfect OEE score of 100% signifies flawless quality (only good parts), peak performance (maximum speed), and uninterrupted availability (no downtime). Achieving a flawless 100% OEE is often impractical, and the industry standard typically hovers around 60%, though the actual OEE figure depends on factors like the specific application, the number of machines, and the complexity of the operation. Nevertheless, striving for perfection in OEE remains an admirable goal.

Consider a scenario where we receive a request for a quote (RFQ) from a prominent, sizeable customer, requesting 25,000 parts

Winning this contract could significantly impact our company’s future growth. After quoting $100,000, the customer accepts our offer. While this is promising news, the downside is that our profit margins are incredibly narrow. Therefore, it is imperative that we maximize our overall equipment effectiveness (OEE). To turn a profit, we must make concerted efforts to expand the blue sections in Figure 3 while minimizing the orange ones.

Dealing with slim profit margins means that any unforeseen issues can have a detrimental impact, potentially erasing profits entirely. Questions may arise, such as whether poor programming is causing damage to our nozzles or if faulty cutting rules are affecting our protective glass. Unplanned downtime can force us into reactive maintenance, disrupting our production schedule and raising concerns about its consequences.

Inadequate programming or maintenance procedures can result in a lower-than-anticipated feed rate, which we initially relied on to calculate our overall run time. This reduction not only diminishes our overall equipment effectiveness (OEE) but also extends the total production duration, all without the need for the operator to intervene and adjust machine parameters. This negatively impacts machine availability.

Additionally, it’s essential to determine whether the parts we manufacture are indeed reaching the customer, or if some of them are ending up as rejects in the scrap bin. A low-quality score in the overall equipment effectiveness (OEE) calculation can have a significant negative impact.

Laser cutting production costs go far beyond just billing for the laser cutting time. Advanced machine tools provide numerous features to assist manufacturers in achieving the required level of transparency to remain competitive. To ensure profitability, it’s crucial to have a comprehensive understanding of all the concealed expenses associated with the production and sale of a product.